Easy Pallet Loading and Unloading

The arrangement of the pallet racking has a minimum of 2.5 metres aisles. Loading and unloading requires no specialised handling equipment and is a straightforward and hassle-free task.

Wide aisle racking for better accessibility

In this system each pallet is individually supported and independently accessible. There is 100% accessibility to each and every pallet.

Standard MHE keeps overall costs down

There is no need for specialist handling equipment to operate wide aisle racking. The aisle width allows for a standard counterbalance truck 3.5 to 4 metres wide. Reach trucks can work in aisles as low as only 2.5 metres wide (depending on height and load).

Increase loading speed

Wide aisle racking is one of the quickest-to-access systems, with full pallet availability. Speed of access is enhanced as it allows multiple access for trucks and pickers who can pass each other in the aisles (where safe to do so).

A limitation of using standard lift trucks is that the racking system’s height is restricted to the maximum lift height of the trucks.

What Is Wide Aisle Racking?

Wide aisle racking is a common and versatile type of pallet racking system used in warehouses and distribution centres. As the name suggests, it features wider aisles, typically ranging from 2.5 meters to 4 meters, between rows of racking. This extra width allows for easy access and movability for standard forklifts or other handling equipment. The racking units themselves are generally placed back-to-back to maximize storage space while maintaining convenient access.

Key Characteristics of Wide Aisle Racking:

Wide Aisles for Free Movement: The most defining feature of this system is the generous aisle width. The aisles allow for smooth, unrestricted movement of forklifts and pallet trucks, making it easier to access pallets stored at various levels without requiring specialised handling equipment. This flexibility is crucial in busy warehouse environments where efficiency is key.

Standard Pallet Racking Configuration:

Wide aisle racking typically uses normal pallet racking structures. These are designed to store a wide variety of goods, from heavy pallets to individual items. The racks can be configured to different heights, accommodating various pallet sizes and weights, making the system adaptable to different industries and storage needs.

Floor Flatness Requirements: In a wide aisle racking system, the aisles are considered “free movement areas.” This means the floor flatness requirements are less rigorous compared to more advanced systems like very narrow aisle (VNA) racking or automated storage systems, which require a high degree of precision in floor levelling to ensure smooth equipment operation.

Ease of Installation and Maintenance:

Wide aisle racking is one of the simpler racking systems to install and maintain. It doesn’t require complex guidance systems, making it a cost-effective option for many businesses. It also offers flexibility in terms of layout, as the racks can be easily adjusted or reconfigured to suit changing needs.

Benefits of Wide Aisle Racking

- Versatility: Suitable for a wide range of industries, from manufacturing, retail to distribution.

- Standard Forklift Access: No need for specialised narrow aisle or reach trucks, reducing equipment costs.

- Fast Order Picking: Wider aisles allow for quicker access to stored goods, which is beneficial in high-turnover operations.

- Flexibility: The racking system can be adapted to store different types of products, pallet sizes and accommodate changes in inventory.

- Familiarity: Most warehouse staff are already familiar with this system, minimising training needs.

- Maintenance Simplicity: Easier to inspect, clean, and repair due to better access.

- Safety: Wider aisles reduce the risk of collisions and accidents in the warehouse.

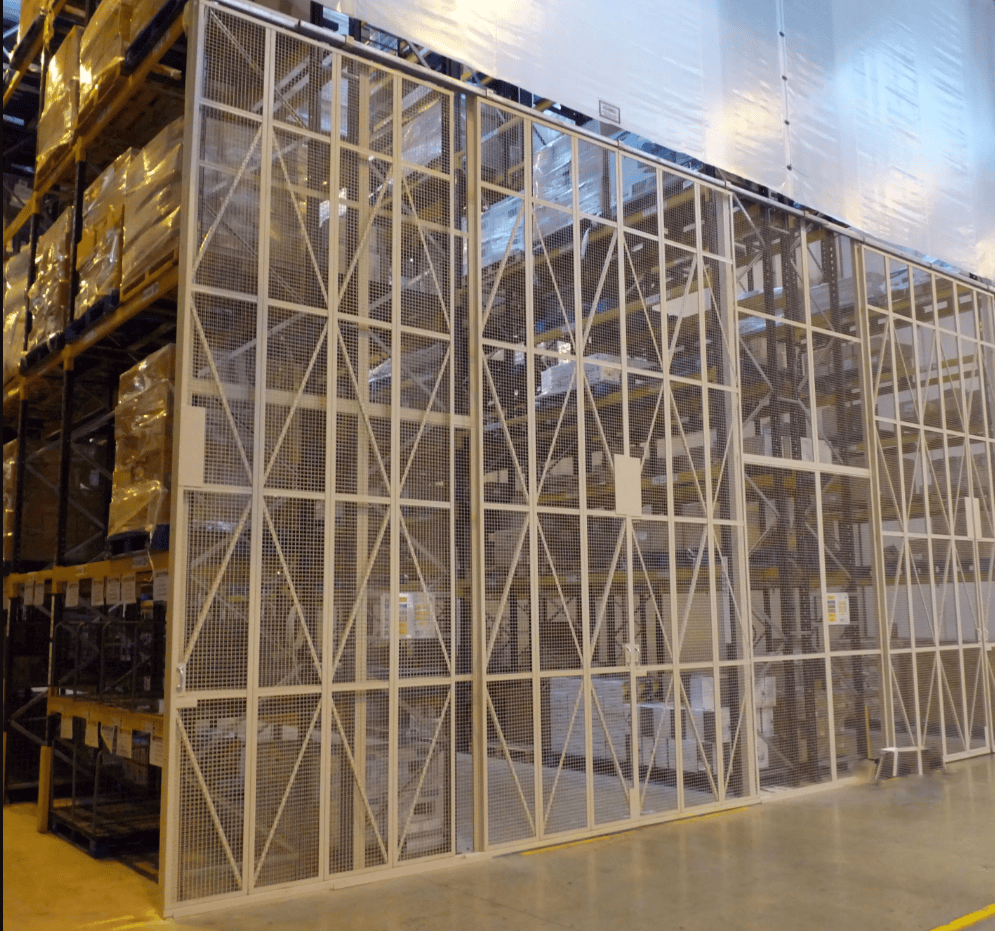

Aerosol and Explosives Cages

NSI can design and install all types of aerosol storage cages to satisfy Insurance Company and Building Control/Fire Officer requirements.

Pallet Racking Repairs

NSI undertake all types of pallet racking repairs for a number of national companies across their portfolios, as part of a holistic system of rack safety.

Racking Inspections

Racking Inspections are integral for rack safety. They are undertaken by our SARI qualified inspector to maintain H&S standards.