Slatted or Close Boarded Timber Decking

It is vital you order your timber pallet racking decking from a partner who will ask about and interpret the specific point loads or UDL loads that your range of pallets create. Pallets that are partially supported by the beams or sit within the beams can create entirely different loads. NSI will calculate this for you and supply the right product for your application. It can also be supplied to provide pick locations under racking.

Warehouse decking is manufactured using kiln-dried softwood and the timber used is structurally graded. The deck boards have battens fixed to the underside that act as the location for the timber deck against the inside faces of the pallet racking beams. It is vital for H&S purposes that these are supplied as a tight fit, otherwise in certain circumstances, lateral beam movement can lead to boards dislodging. Warehouse decking is assembled using automated nailing machines to enable maximum strength and nailing accuracy.

Warehouse decking is quick and easy to install with no fixings required. They simply drop over the pallet racking beams. For external or high humidity applications the warehouse decking can also be supplied using pressure-treated timber to provide a long-lasting solution.

Chipboard and MDF Decking

NSI can design, supply and install chipboard or MDF decking for long-span shelving or picking locations under pallet racking. In order to protect you, it is essential that the duty of material is calculated to take the loads you require. It can be supplied in sheet form only, but most typically we will fix location battens or blocks to the underside to provide location against the shelving or racking beams. The decks will be machine manufactured off-site and thus pre-battened to ensure an exact fit to your beams.

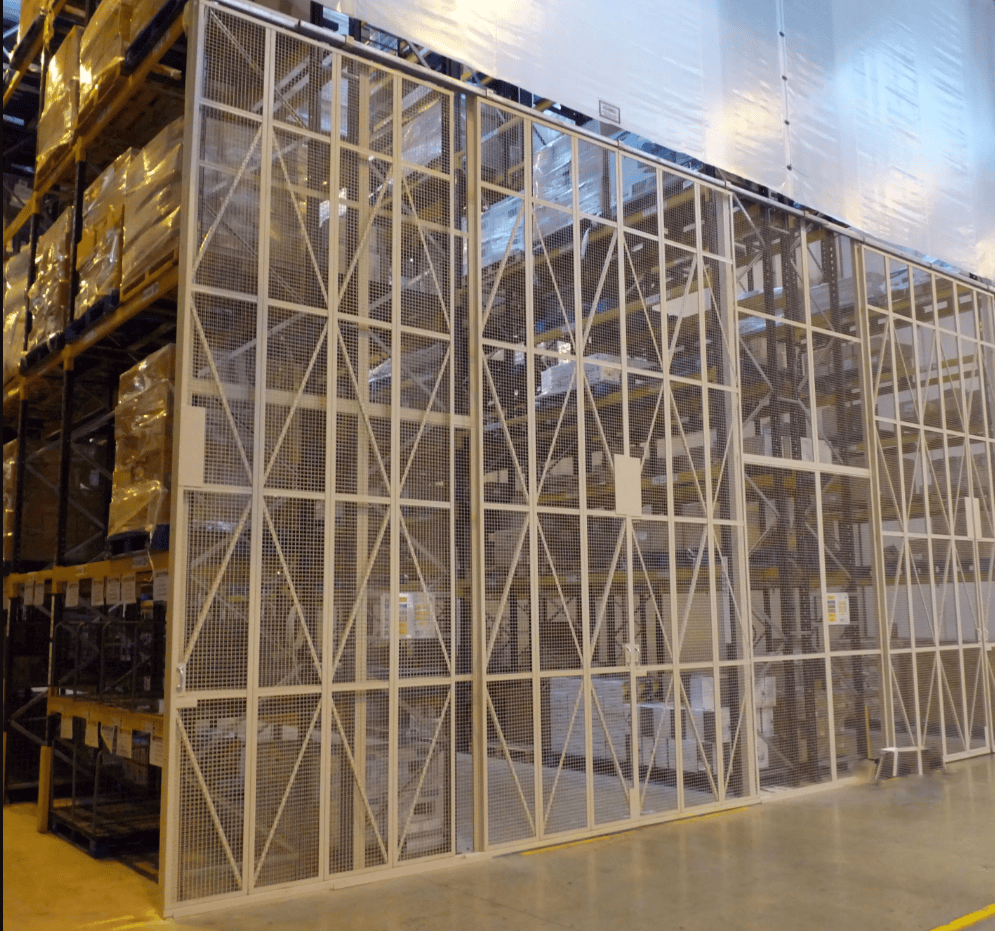

Aerosol and Explosives Cages

NSI can design and install all types of aerosol storage cages to satisfy Insurance Company and Building Control/Fire Officer requirements.

Shuttle Racking System

For clients for whom ultra-high density pallet storage is important, a shuttle racking system can be the answer. The concept is based around the fact that the forklift never enters the racking, individual pallet movements being conducted on intelligent RF guided shuttles that operate on rails millimetres below each pallet.

Pallet Racking Repairs

NSI undertake all types of pallet racking repairs for a number of national companies across their portfolios, as part of a holistic system of rack safety.

Racking Inspections

Racking Inspections are integral for rack safety. They are undertaken by our SARI qualified inspector to maintain H&S standards.