LIFO and FIFO Pallet Systems

Pallet Live applications fall into two main categories;

- LIFO – push-back racking, with the leading pallet, pushed back into dense pallet storage, either using a roller or trolley system.

- FIFO – based pallet live systems, feature loading at the rear and picking from the front of a dense block of storage, with gravity rollers or trolleys presenting pallets for picking at the front.

Brake rollers and pallet separator mechanisms at the pick end ensure the safe passage and retrieval of pallets.

Benefits of Pallet Live and Push Back Racking;

- Significant increase in pallet storage density.

- The increase in efficiency of pallet live over conventional racking can be up to 60%.

- Efficient preparation for despatch at the loading dock.

- Significant reduction of travel times.

- Good overview of all items on stock.

- Increased productivity due to separate loading and picking aisles on pallet live.

- Automated loading and/or retrieval are possible in both pallet live and push-back racking.

LIFO – Push Back Racking

- Pallets are loaded in sequence. During loading, pallets are pushed back to utilise the full depth of the racking. Gravity pushes the next pallet to the front when one is removed.

- Pallets are loaded and retrieved from one face only to optimise space.

- Quick and easy individual product SKU access is by each slot rather than by lane or level.

- Provides good occupancy rates within a high-density system and enables a variety of pallet types to be stored together.

- Conventional forklift trucks can be used.

LIFO – Gravity Fed Racking

- Great for taking product direct from production lines.

- Each roller bed supports one SKU.

- The number of items per SKU and the incline determine the lane length

- When used as dispatch lanes, 13 deep runs ensure that pallet live storage racking can make for easy 26 pallet complete lorry loads.

- Can lead to reduced vehicle waiting time as well as travel time for in-house transport and dramatically minimises the footprint of dispatch lanes.

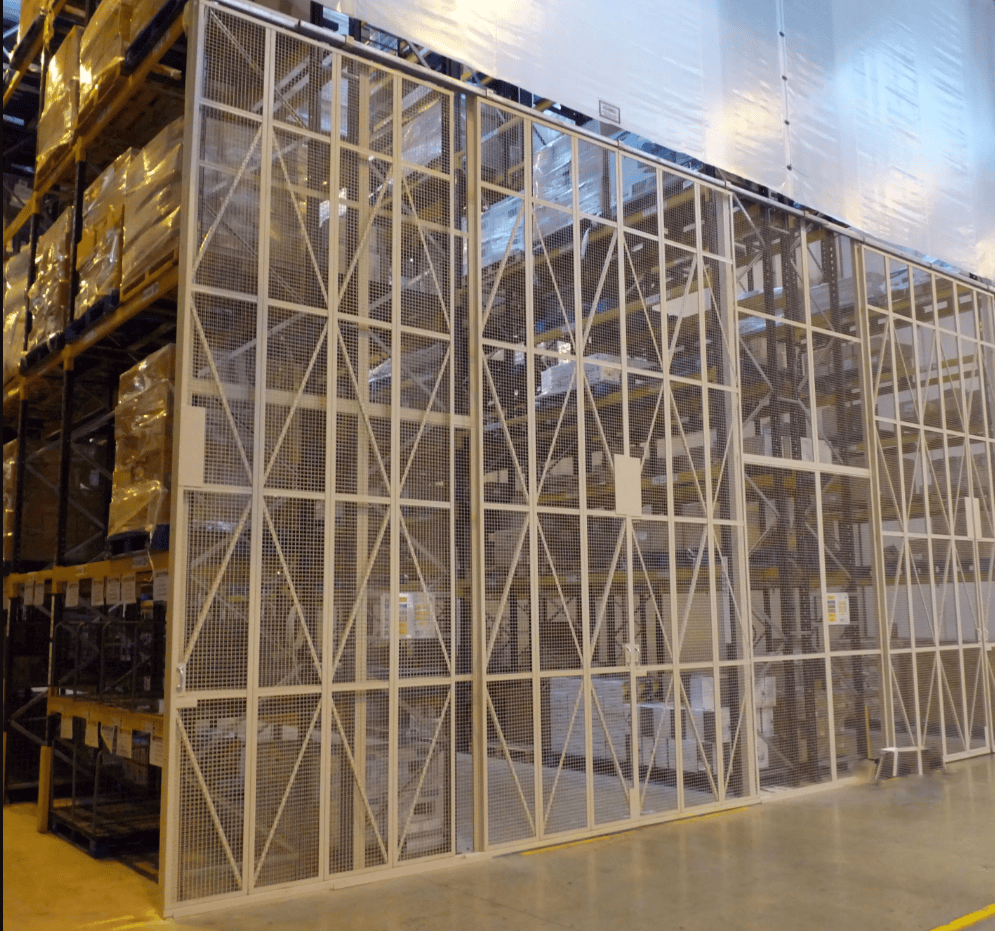

Aerosol and Explosives Cages

NSI can design and install all types of aerosol storage cages to satisfy Insurance Company and Building Control/Fire Officer requirements.

Shuttle Racking System

For clients for whom ultra-high density pallet storage is important, a shuttle racking system can be the answer. The concept is based around the fact that the forklift never enters the racking, individual pallet movements being conducted on intelligent RF guided shuttles that operate on rails millimetres below each pallet.

Pallet Racking Repairs

NSI undertake all types of pallet racking repairs for a number of national companies across their portfolios, as part of a holistic system of rack safety.

Racking Inspections

Racking Inspections are integral for rack safety. They are undertaken by our SARI qualified inspector to maintain H&S standards.