High-Density Storage

By dispensing with access aisles, drive-in racking provides high-density storage to increase capacity by some 60-80% over ‘conventional aisle’ racking. Pallets are stored on support rails in the depth of the racking, and forklift trucks can enter these ‘storage lanes’ to deposit or retrieve loads. Access can be from one end (the true ‘drive-in’ configuration) or from both ends (‘drive through’, for improved stock rotation).

Drive-in pallet racking can have heights of up to 11 metres allowing the full height and floor area of the building to be used to provide maximum cubic storage space.

Benefits of Drive-in Pallet Racking:

- Designed for situations when maximum density, economical pallet storage is more important than stock selection or rotation

- Suitable for fragile loads and seasonal goods with low stock rotation

- Ideal for cold / chill storage and bulk storage applications

- Conventional fork-lift trucks can be used

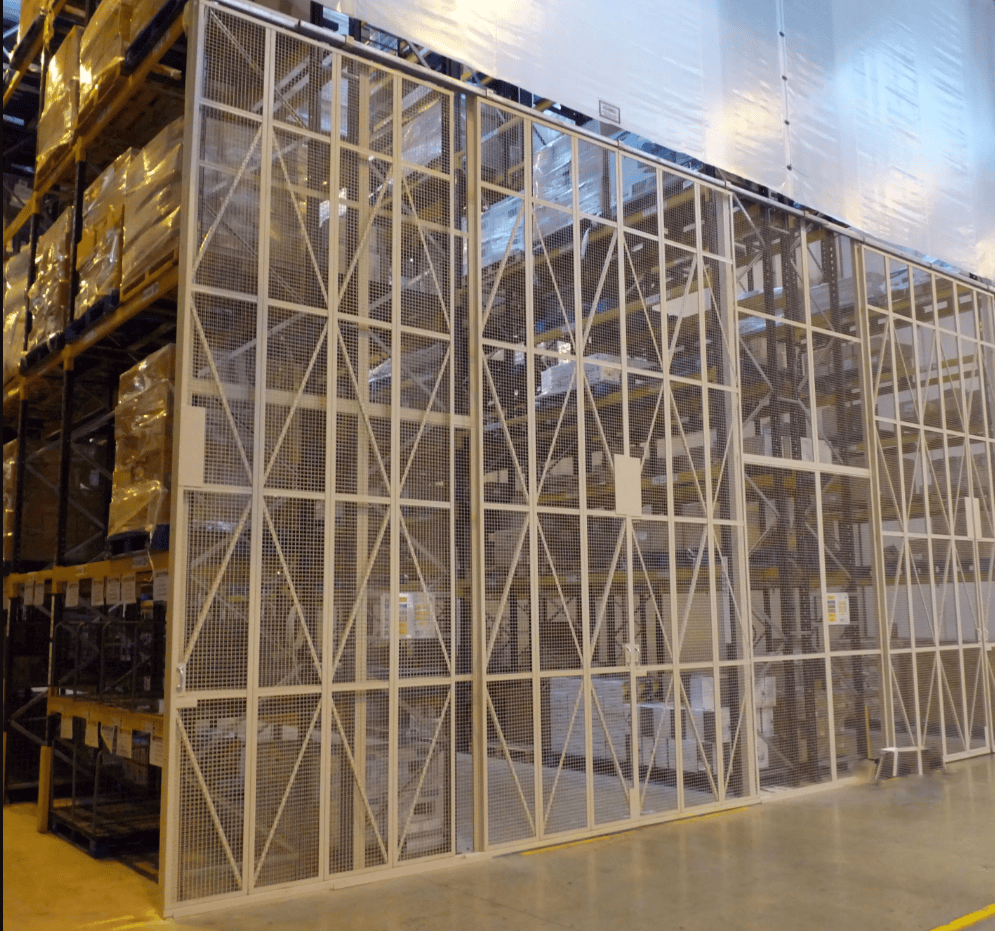

Aerosol and Explosives Cages

NSI can design and install all types of aerosol storage cages to satisfy Insurance Company and Building Control/Fire Officer requirements.

Shuttle Racking System

For clients for whom ultra-high density pallet storage is important, a shuttle racking system can be the answer. The concept is based around the fact that the forklift never enters the racking, individual pallet movements being conducted on intelligent RF guided shuttles that operate on rails millimetres below each pallet.

Pallet Racking Repairs

NSI undertake all types of pallet racking repairs for a number of national companies across their portfolios, as part of a holistic system of rack safety.

Racking Inspections

Racking Inspections are integral for rack safety. They are undertaken by our SARI qualified inspector to maintain H&S standards.