Anti-Collapse Mesh Systems

Due to the range of options and range of benefits, NSI is often installing netting systems for our clients.

- Proven safe system for the containment of up to a 1000kg pallet load

- Reduced installation time

- Maintenance free

- Various net sizes available

- Verified loadings and consistent loading capacity

- Damage resistant

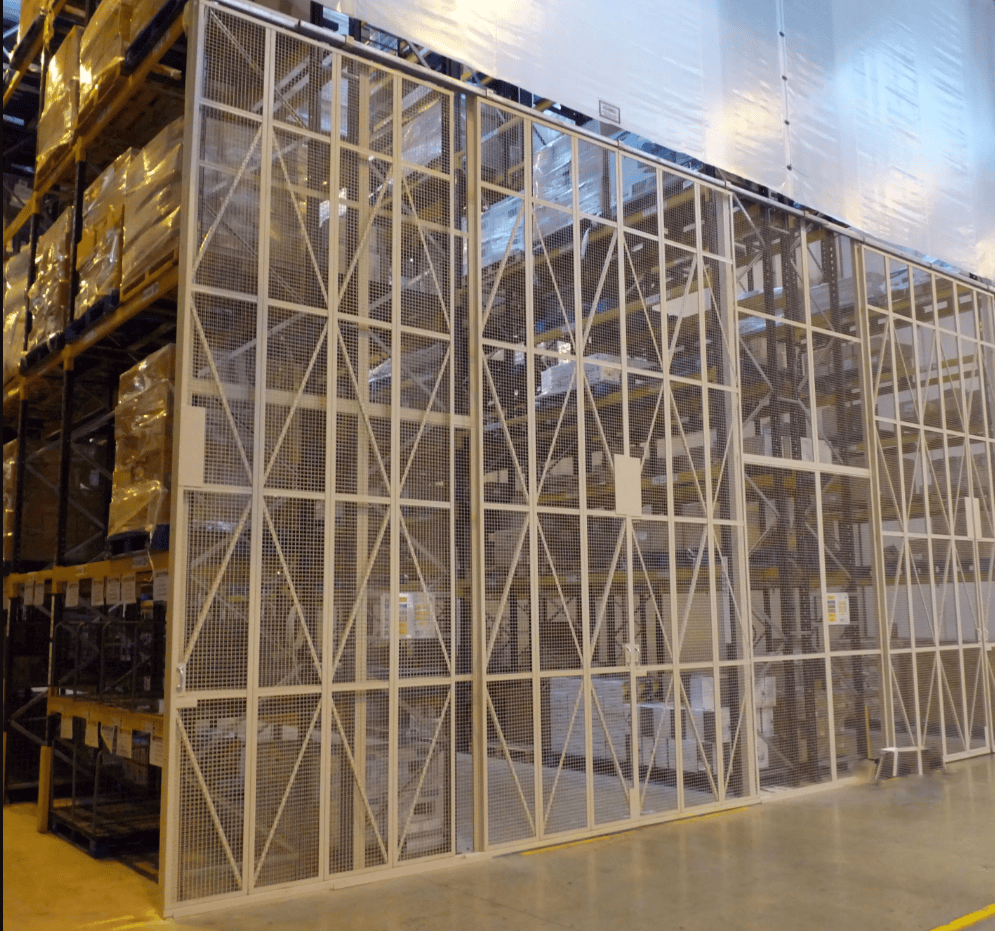

Steel Mesh Panel Anti-Collapse

A 50mm gauge mesh is installed in a brick pattern using standoff brackets normally 150mm from the back of the rack. It would typically be installed where single runs of pallet racking back on to an area where a pedestrian or fork-lift truck could be hit by product collapsing out of the rear of the rack. This mesh racking protection is usually installed when the pallet racking goes up initially, but we can also retrofit this for you.

Steel anti-collapse mesh panels can also form an integral part of Aerosol and Explosives Cages, although the gauge and duty of the mesh used need to be carefully selected in liaison with insurers and Building Control/Fire Officers. NSI source products from a range of suppliers so can always find the most economical equipment for your situation.

Aerosol and Explosives Cages

NSI can design and install all types of aerosol storage cages to satisfy Insurance Company and Building Control/Fire Officer requirements.

Shuttle Racking System

For clients for whom ultra-high density pallet storage is important, a shuttle racking system can be the answer. The concept is based around the fact that the forklift never enters the racking, individual pallet movements being conducted on intelligent RF guided shuttles that operate on rails millimetres below each pallet.

Pallet Racking Repairs

NSI undertake all types of pallet racking repairs for a number of national companies across their portfolios, as part of a holistic system of rack safety.

Racking Inspections

Racking Inspections are integral for rack safety. They are undertaken by our SARI qualified inspector to maintain H&S standards.