Why are racking inspections needed?

- Racking inspections are an integral part of NSI’s System of Rack Safety

- All pallet racking should be properly maintained and in good order. Racking safety inspections are required to comply with the PUWER (The Provision and Use of Work Equipment Regulations) guidelines, in order to maintain health and safety standards and to prevent and minimise the effect of accidents in the workplace. The regulations clearly state that racking should be regularly inspected by a person proven competent to do so.

- The majority of our customers elect for an annual formal racking inspection by our qualified SARI (SEMA Authorised Rack Inspector), however, in incidents of high traffic or serious damage, these formal inspections will be carried out every 6 months. In addition, customers also conduct their own weekly and monthly visual checks, trained by our SARI in how to do this.

Benefits of Regular Rack Inspections

- All racking inspections are carried out in accordance with SEMA Racking Inspection guidelines and ensure your racking is compliant with the law.

- We offer a fast efficient pallet racking inspection service backed up by a detailed rack inspection report and comprehensive rack damage summaries which break down the damage by risk level and damage type.

- Easy to understand, jargon-free inspection report.

- We provide a personal service ensuring confidence and continuity from a SEMA-approved rack inspector (SARI), who will get to know your installation in great detail and offer an easy-to-understand, jargon-free inspection report.

- A formal notice of all RED RISK items is issued on the day of the inspection so immediate action can be taken by you to offload an unsafe rack.

- We also offer customised onsite pallet rack inspection training allowing you to conduct your regular internal weekly and monthly inspections in compliance with HSE guidelines as defined in HSG 76.

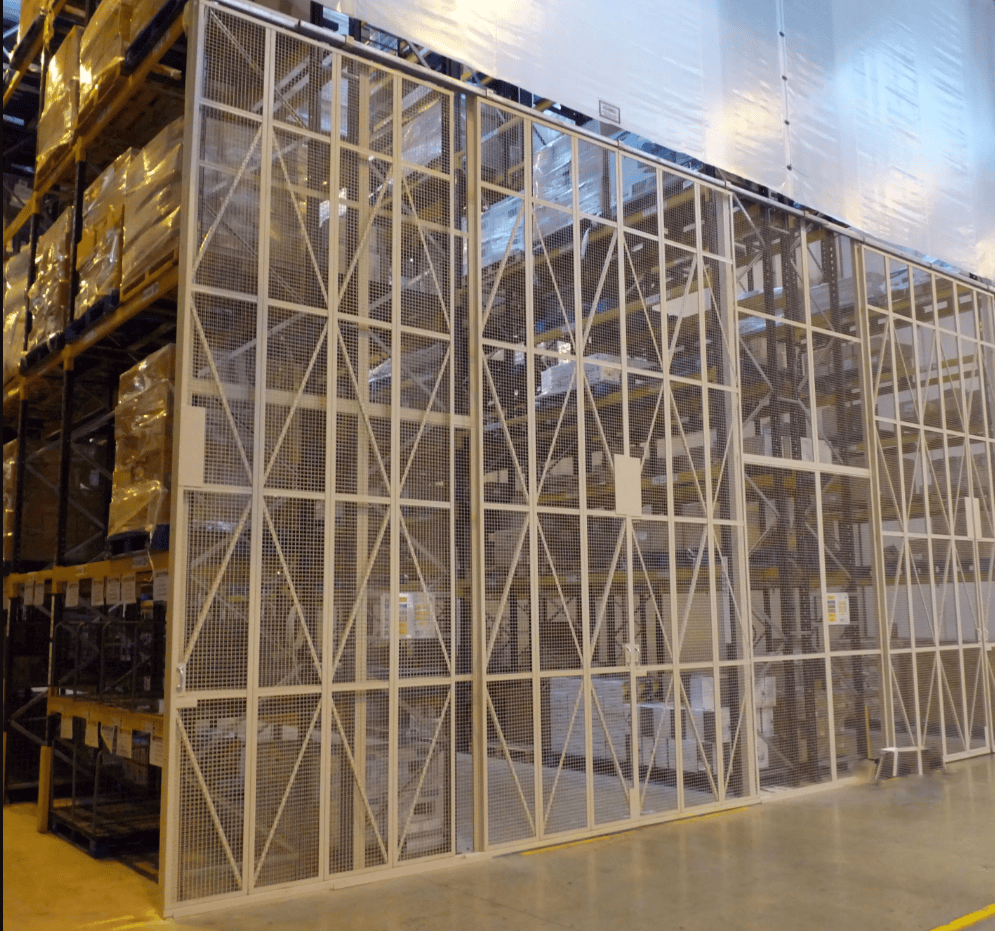

Aerosol and Explosives Cages

NSI can design and install all types of aerosol storage cages to satisfy Insurance Company and Building Control/Fire Officer requirements.

Shuttle Racking System

For clients for whom ultra-high density pallet storage is important, a shuttle racking system can be the answer. The concept is based around the fact that the forklift never enters the racking, individual pallet movements being conducted on intelligent RF guided shuttles that operate on rails millimetres below each pallet.

Pallet Racking Repairs

NSI undertake all types of pallet racking repairs for a number of national companies across their portfolios, as part of a holistic system of rack safety.

Pallet Racking Decking

Warehouse pallet racking decking can be used to provide additional support to pallets that don’t naturally overlap.

Pallet Live and Push Back Racking

Pallet live racking and push back pallet racking are commonly chosen warehouse storage solutions to maximise space in the warehouse flow process.

Narrow Aisle Racking

Narrow aisle pallet racking and very narrow aisle racking (VNA) can offer some of the same flexibility as wide aisle racking.

Mobile Racking

Mobile pallet racking systems are assembled by mounting individual runs of the rack onto heavy-duty mobile racking bases equipped with electric motors running on tracks embedded in the warehouse floor.

Drive-in Racking

For a cost-effective solution for storing palletised goods within a limited space in your warehouse or business. Drive-in pallet racking offers a relatively low cost per pallet stored.

Cantilever Racking

Cantilever Racking is generally designed to maximise storage capacity, accessibility and presentation of long or irregular items.

Anti-Collapse and Racking Mesh

We can supply and install the more traditional steel panels, anti-collapse mesh for racking system or increasingly the more flexible anti-collapse netting system, supplied in a range of sizes.

Wide Aisle Pallet Racking

The most commonly used system for storing palletised unit loads is wide aisle pallet racking. Fast throughput and ease of unloading/loading, make wide aisle racking extremely popular.

Pallet Racking Gallery

We Are SEMA Approved

We have been awarded a Highly Commended Status by the Storage Equipment Manufacturers Association (SEMA).

NSI Workplace Equipment

NSI supply a huge range of over 20,000 items of workplace equipment to help fully equip your premises from one, easy to deal with source.

Why Use NSI Projects?

With over 40 years of experience, NSI Projects conducts racking inspections in line with SEMA Racking Inspection guidelines, ensuring your racking complies with legal standards.

For a formal inspection, either annually or every six months, by our qualified SARI (SEMA Authorised Rack Inspector), contact our experts today on 0800 027 1966.